robert albrecht patent hardness tester|tablet hardness testing methods : trading Tablet hardness is an important quality characteristic because of its relationship to many other tablet properties. The Pfizer tablet hardness tester provides an improved method for .

Resultado da Kkkkkkkkkkk, trollei

{plog:ftitle_list}

Visit ESPN for NBA live scores, video highlights and latest news. Stream games on ESPN and play Fantasy Basketball.

Albrecht Robert Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the .The present invention relates to a machine for testing or determining the hardness or resistance to crushing of pharmaceutical and other tablets. In the manufacture of tablets, of which large. .The Monsanto tablet hardness tester-Picture Courtesy: Biolinxlabsystem. This device for tablet hardness assessment is the first time commenced in 1953 with a US patent by the scientist’s .According to the International System of Units, the units of measurement of tablet hardness mostly follow standards used in materials testing. • Kilogram (kg) – The kilogram is recognized by the SI system as the primary unit of mass.• Newton (N) – The Newton is the SI unit of force; the standard for tablet hardness testing. 9.807 Newtons = 1 kilogram (at one G, earth surface gravity).

Introduced in 1953, under US Patent No. 2,645,936 by Robert Albrecht-Like Stokes Monsanto, it also measures the diametrically applied force required to break a tablet. - It measures the .Tablet hardness is an important quality characteristic because of its relationship to many other tablet properties. The Pfizer tablet hardness tester provides an improved method for .

Tablet hardness testers first appeared in the 1930s. In the 1950s, the Strong-Cobb tester was introduced. It was patented by Robert Albrecht on July 21, 1953. and used an air pump. The .

Tablet hardness testers first appeared in the 1930s. In the 1950s, the Strong-Cobb tester was introduced. It was patented by Robert Albrecht on July 21, 1953. and used an air pump.When testing tablets of uniform hardness and dimensions, a definite relationship was found to exist between the Strong Cobb and the Monsanto tablet hardness testers. Single instruments .Abstract. When testing tablets of uniform hardness and dimensions, a definite relationship was found to exist between the Strong Cobb and the Monsanto tablet hardness testers.Articles Comparison and correlation of the strong cobb and the monsanto tablet hardness testers Archie McCallum, John Buchter, Robert Albrecht, †* Strong, Cobb and Company, Inc., Cleveland, Ohio Strong, Cobb and Company, Inc. Cleveland Ohio †Designer of the Strong Cobb Hardness Tester. Abstract When testing tablets of uniform hardness .

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .Several variants of tablet hardness testers ranging from manual to automatic are currently being utilized (Bavitz et al., 1973; Fairchild and Michel, 1961; Goodhart et al., 1973; McCallum et al., 1955). In addition to the traditional quality control tests for tablets, coated tablets are evaluated for the characteristics of the coating films. .later by Robert Albrecht (6) and eventually dis- Kg. Received June 22, 1961, from the Process Control Labora- tory, Pharmaceutical Products Dept., Chas. Pfizer & Co., Inc., Brooklyn, N. Y. Accepted for publication July 20, 1961. Fig. 1.-Stokes (formerly Monsanto) tablet hardness tester. tributed as the Strong Cobb tablet hardness tester

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

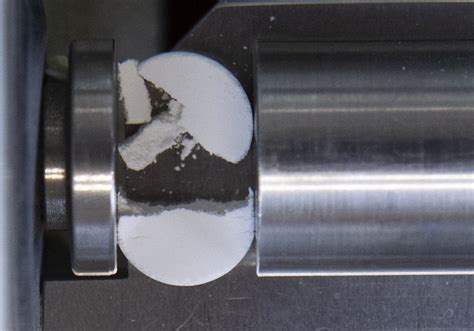

Tablet hardness testers first appeared in the 1930s. In the 1950s, the Strong-Cobb tester was introduced. It was patented by Robert Albrecht on July 21, 1953. and used an air pump. The tablet breaking force was based on arbitrary units referred to as Strong-Cobbs. The new one gave readings that were inconsistent to those given by the older testers. Tablet hardness testing, is a laboratory technique used by the pharmaceutical industry to test the breaking point and structural integrity of a tablet "under conditions of storage, transportation, and handling before usage" The breaking point of a tablet is based on its shape.It is similar to friability testing, but they are not the same thing. . But it was only patented in 1953 by Robert Albrecht and called the Strong-Cobb tester. At the time, it was utilized as an air pump. . The hardness tester can also be used to ensure the quality of cosmetic products, including lipstick, brow or lip pen, and wax and cream products. More than the hardness, the industry relies on the results of .Investing in a DuraScan G5 hardness tester significantly reduces costs in the laboratory. The fast preparation of your testing tasks, the saving of templates for identical parts, many automated processes and the fully automatic testing process shorten the time required for hardness testing and therefore save money every day.

The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .Technical Articles Pfizer Tablet Hardness Tester H.J. Fairchild, F. Michel, Abstract Hardness has long been regarded as an important quality characteristic of tablets. Until recently, only two practical types of tablet hardness testers were available to the pharmaceutical industry. A new addition to this field of testing has just been made.Vickers hardness testing is integral to manufacturing and production processes, enabling quality control and process optimization. This hardness tester aids in evaluating the hardness and integrity of materials at various stages, from raw materials to finished products, ensuring consistent quality and reliability. 4. Metallurgy Starrett Benchtop Hardness Testers are advanced measuring instruments designed for accurate and reliable hardness testing in a variety of industrial and manufacturing applications. With user-friendly software and advanced features such as data output and programmable load and dwell times, these testers provide unparalleled precision and efficiency.

It is similar to friability testing, [1] but they are not the same thing. Tablet hardness testers first appeared in the 1930s. [3] In the 1950s, the Strong-Cobb tester was introduced. It was patented by Robert Albrecht on July 21, 1953. [4] and used an air pump. The tablet breaking force was based on arbitrary units referred to as Strong-Cobbs. [3]The Strong-Cobb is a unit with a very unusual name for a unit of measurement since it is named after the company, Strong-Cobb Inc. The inventor of the hardness tester was Robert Albrecht, the plant engineer for the Strong-Cobb Company. He sold the patent to the company for .00. Further reading. J. E. Rees . P. J. Rue . amp . 1978 .

Model No. PHT-1900 Features. State of the art, digital portable hardness tester is designed to test the hardness of large hard metal parts. Clean crisp display shows the incredible functions that can only be found on this new portable .

Hardness testing plays an important role in materials testing, quality control and acceptance of components. search. Search search close search cart . The patent application was approved on February 11, 1919, and later, in 1924 an improved design patent was granted.

Robert Albrecht; When testing tablets of uniform hardness and dimensions, a definite relationship was found to exist between the Strong Cobb and the Monsanto tablet hardness testers. Single .

Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to .A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a measuring transducer. The DuraJet, ZHR Touchscreen and ZHR8150CL models are software controlled hardness testing machines with automatic .

Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

innovatest hardness tester

What Is Hardness Testing? Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for comparing and selecting materials, as well as ensuring quality control in manufacturing or hardening processes.Hardness Testers from Newage Testing Instruments - Quality Assured! Newage Testing Instruments is an established manufacturer and worldwide supplier of hardness testers and accessories, providing you with the ideal solutions for all your research and quality needs.Designed to provide a fully automated, dedicated, and lean hardness tester, the Wilson VH3100 is the workhorse of the VH3000 series. Featuring a load cell range of 0.05-10kgf and 3-position virtual turret, this system significantly reduces complexity by aligning its indenter, objectives, and overview camera at a fixed location.Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

tablet hardness testing tool

A full selection of hardness testers, testing machines, testing equipment and accessories for Vickers, Knoop, Brinell and Rockwell hardness testing from Struers, the world’s leading materialographic and metallographic equipment supplier.

tablet hardness testing methods

WEB22 de mar. de 2022 · No domingo (20), o Telegram informou que irá monitorar os 100 maiores canais brasileiros da plataforma, de forma a combater a disseminação de .

robert albrecht patent hardness tester|tablet hardness testing methods